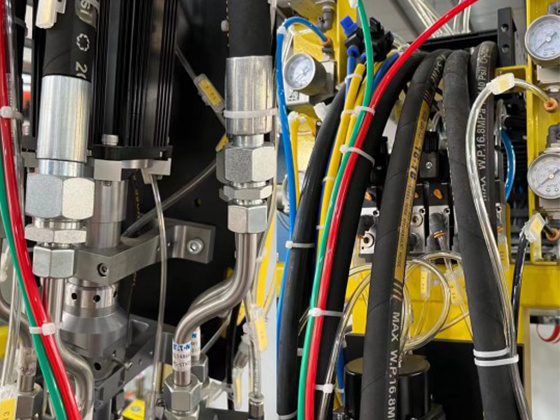

Mining high-pressure hose assembly in the use of what problems are likely to occur?

Jun 28,2024

The reasons for the failure of mining high-pressure hose assembly and intermediate joint components are summarized as follows.

( 1 ) hydraulic ( emulsion ) system pressure source to take three piston pump or five piston pump, rated pressure is high, flow rate is large, the amount of pressure pulsation is large, pipeline components are easy to fatigue damage. Especially the main liquid supply pipeline, long time in the pulse of high pressure state work, high pressure hose weak links, such as seals, U-type card, high pressure hose joints, etc. The chance of failure is much higher than the bracket within the high-pressure hose failure frequency, because the latter high-pressure hose is only in the bracket action to withstand the high-pressure, the role of the time is very short, resulting in a different mechanism of failure.

( 2 ) emulsion medium low privacy, density, corrosion resistance is relatively poor, especially in different mining areas, water pH varies greatly, the use of lax management, downhole emulsion is often less than the specified oil-water ratio, rubber in the long-term immersion in this medium is bound to deteriorate, hardening, aging.

( 3 ) due to the use of downhole equipment, media cleanliness is low, the media hostage gas more, on the one hand, very easy to occur cavitation, cavitation occurs, the peak pressure can be more than 1G P a; On the other hand, high speed and large flow rate of emulsion hostage to small impurities, impact on the inner surface of the pipeline and the joints components, will be ploughed out of a ditch marks, resulting in wire erosion. Damage to the inner rubber layer of the high-pressure hose accelerates the corrosion of the hose preparation steel wire mesh, reducing the pressure strength of the high-pressure hose. Pressure wave on the high-pressure hose assembly and coupling components to produce a strong impact, and lead to high-pressure hose assembly and coupling components dangerous section of the fracture (broken) crack.

( 4 ) The coal mine production environment is dusty and humid, and the water is weakly alkaline. The vibration of the pipeline and environmental objects friction, so that the high-pressure hose surface rubber abrasion, joint assembly surface anti-corrosion layer off, promoting the damage process.

( 5 ) production of high-pressure hose assembly and intermediate joint components of the factory is mostly small and medium-sized enterprises, technology, equipment, capital and other constraints, and some even do not process according to the drawings of the process requirements, high-pressure hose assembly and piping accessories can not meet the technical requirements of product quality varies, low strength, short life, serious pollution, for the sudden safety accidents buried hidden dangers.

( 6 ) design layout is unreasonable. Under normal circumstances, the main high-pressure hose to withstand internal pressure and a certain (bending) external forces, incorrect layout, so that the high-pressure hose for a long time in the role of additional additional forces (tensile, torsion), reducing the service life of the high-pressure hose assembly.

( 7 ) Failure of piping components over life use. Due to the inability to test and accurately determine whether the high-pressure hose and piping components fail or reach the service life, there are a large number of over-life use of components (according to foreign regulations, high-pressure hose factory 1 year after the validity of these high-pressure hose is often easy to use in the process of failure, resulting in an increase in the failure rate.

Previous:

Recommended

JIU LONG Secures U.S. MSHA Certification, Advancing Global Strategy