Selection of rubber hoses, fittings, installation, maintenance measures

Jun 28,2024

In the automotive industry, due to special environmental temperature requirements, ordinary nitrile rubber hose can not meet the expected use requirements, so the need to choose EPDM rubber hose; if the equipment through the rubber hose to transport oil, can not choose styrene-butadiene rubber hose, or poor oil resistance affects the operation of the equipment and even the life of the equipment; the specific working pressure must be considered a factor of safety, 3 or 4 times, do not get away with less than the working pressure hose; fuel dispenser hose need to consider the safety factor, abrasion resistance and other special requirements, etc.; fuel dispenser hose need to consider the special requirements of abrasion resistance. Do not use the hose below the working pressure, which may cause serious safety accidents; fuel dispenser hose needs to consider the flame retardant factor, wear resistance and other special requirements.

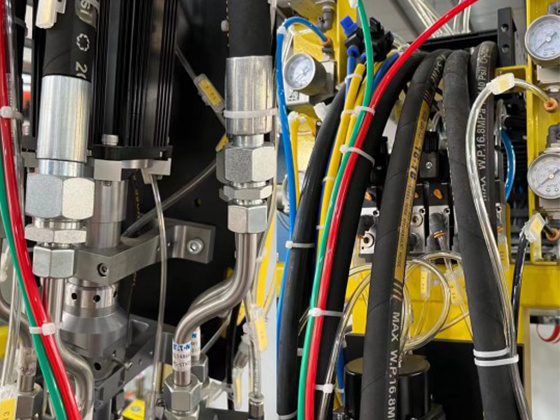

From the picture, it is not difficult to see that the assembly users use the inner diameter of 16mm steel wire braided fuel hose, its fittings are mainly made of stainless steel fittings. Nowadays, more and more users will choose a higher cost of stainless steel fittings to ensure the stability of equipment operation, but also because the stainless steel material to bring you reliable quality assurance, its corrosion resistance is excellent, so that the market is also enduring, flourishing. It is worth noting that the buckling work can not be ignored, whether appropriate and reasonable buckling needs a long time of experience and the correct theory to verify that often the source of some accidents is due to excessive buckling or buckling improperly. In terms of buckling pressure will also put forward technical support to meet the one-stop service needs of our customers.

In addition, the rubber hose has a "minimum bending radius" value, even if the 10cm hose can play a great use, but in the installation and assembly time, need to pay attention to the correct use of the tube body: for example, can not exceed the maximum bending radius, or the tube body is twisted, pay attention to the tube body in a timely manner in the operation of the machine whether or not the appearance of the changes occurred, and so on. We also often see the outer ring of the tube body wrapped around the black or other colors of the spiral sheath, the purpose of this to protect the internal pipeline, but also can play a part of the effect of heat insulation. In addition, regular maintenance measures and maintenance is also essential, so as to efficiently ensure the normal operation of the equipment.

Previous

Recommended

JIU LONG Secures U.S. MSHA Certification, Advancing Global Strategy