Glossy Hose Vs Fabric-Faced Hose

Jun 28,2024

Hydraulic hose in the engineering machinery, agriculture, mining machinery and other major fields are widely used, pressure, medium, temperature or other factors of the diversity of the same time also creates a rich diversity of hose types. With technological innovation and breakthroughs, rubber hoses made in China can increasingly meet a variety of special requirements, specific environments. As always, we will continue to innovate and make breakthroughs to create more and more safe and reliable fluid solutions and technical support for hydraulic systems.

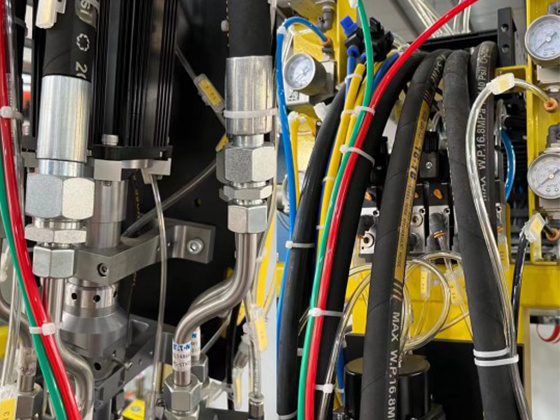

On the market, you can see the colorful rubber hose, high pressure and high pulse winding hose, red steam hose or wear-resistant thick sandblasted hose, at the same time, it is not difficult to find part of the equipment machine began to install the use of glossy rubber hose, instead of the original traditional fabric surface rubber hose.

From the appearance, it is obvious that the smooth outer surface to replace the clear pattern of the cloth surface, it seems to have more of a sense of luster and even be called by the customer "sense of superiority", some people will be puzzled by the outer layer is a plastic alternative to rubber, in fact, this answer is right is not entirely correct; this should be distinguished from the process - vulcanization process, cloth surface tube need to be wrapped around the water cloth, and then the rubber tube will be used to replace the original traditional cloth surface rubber tube. The surface pipe needs to be wrapped around the water cloth after vulcanization, while the glossy pipe is vulcanized using the plastic wrapping process, so the appearance of the finished product is different, but the two materials need to be stripped from the outside of the pipe body after vulcanization, so we see whether the glossy pipe or the external material of the fabric pipe is still rubber. On the function and role of the point of view, glossy tube in the assembly cleaning, easier to organize, reduce the use of cleaning difficulty; glossy surface friction is smaller, smooth surface, friction resistance is smaller, thus the more wear-resistant. Of course, all the good conditions are also based on mature and stable technology as well as reliable and excellent materials.

The position of the traditional and stable hose with fabric surface does not seem to be threatened, and still occupies the majority of the market share. One of the reasons for this is that the cost and waste of glossy hose is higher than that of fabric hose, so there are advantages for each, and it is difficult to distinguish between them. The choice and the future is still left to the market to decide!

Recommended

JIU LONG Secures U.S. MSHA Certification, Advancing Global Strategy